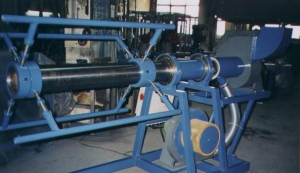

PE liner blower machines for open top big bags

Machine was deisgned to speed up the process of completing the manufactured open top big-bag with inner PE liner.

Pneumatic arms of machine provide accurate contact between the PE liner and inner walls of big-bag, without wrinkles.

PE liner is placed on the arms of the machine. Span of arms is pneumatically adjusted, depending on the dimensions of bag. The operator applies glue on the whole surface of the liner (it is also possible to connect the liner and the bag by means of double-side adhesive tape).

The machine does not require any movement from the operator during glue application - its arms can rotate 360 degrees.

After glue is applied, the bag is placed on top of the liner. The next step is 'blowing' of the liner - during this process, both elements of final big-bag are being connected together.

When cycle ends and compressed air supply stops, the arms of the machine return to their home position and ready-made bag can be taken off the machine.

Thanks to possibility of adjustment of machine arms, assembly of liners inside big-bags of changeable dimensions is possible.

Basic technical data:

- range of dimensions for square bags (can be adjusted according to expectations of the customer): from 60 x 60 cm to 105 x 105 cm

- range of dimensions for rectangular bags (can be adjusted according to expectations of the customer): from 70 x 90 cm to 80 x 125 cm

- maximum length of bags: 200 cm

- capacity: 3-4 bags/min. (depending on skills of operator)

- power consumption: 1,1 kW

- power supply: 230/380 V; 50-60 Hz

- compressed air supply: 8 bar; 800 l/h

- dimensions of the machine: 460 (l.) x 110 (w.) x 220 (h.) cm