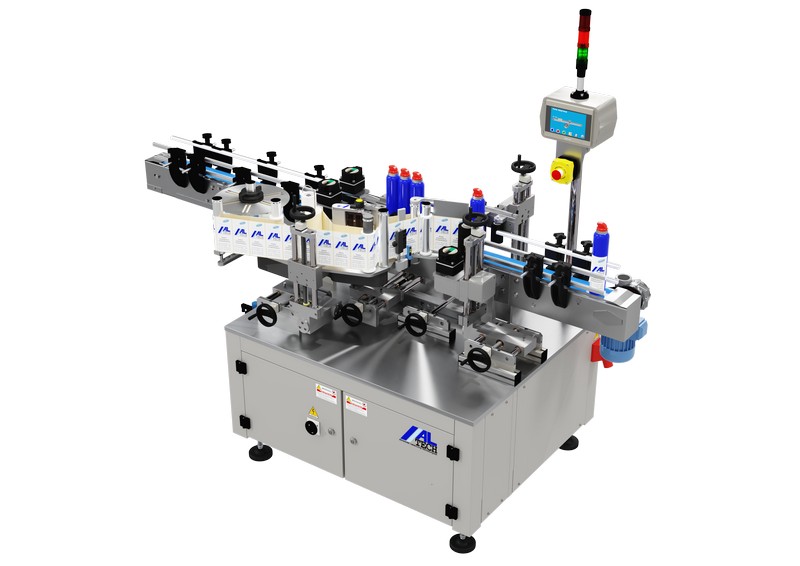

ALline C - Wraparound labelling system

The ALline C labelling machine is ideal for applying wraparound labels to cylindrical packages,

The ALline C labelling machine is ideal for applying wraparound labels to cylindrical packages,

typically food, chemical, cosmetics and pharmaceutical products, in plastic, glass or metal bottles, jars etc.

Performance ranges from 80-200 pcs/min (depending on product dimensions and label size), up to 300 pcs/min in dedicated configurations.

The solid and compact base can accommodate ALstep or ALritma series label applicators in an easy-access protective cabinet.

Product Transport

ALline C can use various types of conveyors for product transport, both slatted (in plastic or in steel) or belt types, of various sizes. Various different devices are available for product spacing, depending on the required product type and performance.

Wrap-around adaptation of the label

For wrap-around/adaptation of the label, various specific wrap-around units are available:

- Simple belt type

- Suction belt type

- Roller type

These give the possibility to label in-phase with print registration or elements present on the product itself.

Possible labelling solutions

Combining different items from the catalogue allows us to create specific configurations for:

- Partial or complete wraparound labelling

- In-phase labelling

- Application of tamper-proof seal labels

- Labelling with slight taper

- Very high-speed labelling, including non-stop version

Adjusting the different units for format/product changes is simple, high-precision and intuitive; the labelling head is equipped with a function to save the parameters for a specific label-product combination, so they can be easily recalled with a code.

The ALline C labeller can be equipped with a wide range of label printing units, for dry, hot or thermal transfer (SATO or compatible) printing of text, expiry dates and barcodes.

Optional Accessories

The modularity of all ALline systems allows them to be equipped with optional components to increase their running time and performance, including:

- High-precision adjustment systems for head inclination and revolution counters for adjustment handles

- Rotary infeed and outfeed tables

- Batch or expiry date markers

- Product flow monitoring devices (minimum infeed/outfeed)

- Label application confirmation with automatic expulsion.