Machines for production of aluminum liners for four-loop bags

Group of machines allowing forming of aluminum liners for four-loop bags.

Group of machines allowing forming of aluminum liners for four-loop bags.

Their general operation mode resembles standard PE liner forming machines. The first section of the machine is what makes a difference.

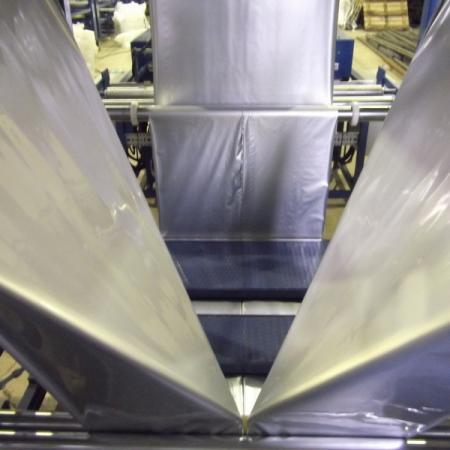

Specially designed unwind unit forms body of the liner out of four aluminum tapes.

These tapes are placed on top of each other (in addition, tapes forming sides of liner are gusseted) and welded together.

Following steps are identical as for PE liner forming.

Welded tube of aluminum foil is straightened by means of dancer rollers.

In next stages of production process, the machine is sealing of top and bottom spouts of the liner.

The final stage is cutting of formed liner.

Ready made liners are manually collected by the operators.

Optionally they can be transferred to vacum conveyor and/or collecting unit.

Basic technical data:

- length of liner: adjustable

- filling spout width: adjustable in range of 17-65 cm

- filline spout length: 60 cm

- side sealing system: continuous sealing

- welding system: heat adjustable sealing bars

- capacity: 1 liners per 45 s.

- power consumption: up to 23 kW

- power supply: 380 V, 50 Hz

- compressed air supply: 6 bars, 300-500 l/min

- dimensions of the machine: 1300 (l.) x 400 (w.) x 220 (h.) cm